The Accumulator

This is actually not the first project that I worked on at Formula Hybrid. I was sort of floating around for my first couple weeks - I honestly didn't do too much. As the year went on, this became a high priority project compared to what I was doing so I was one of the people assigned to it to get things moving. Looking back, it's funny because I never intended to work on this project at all and now it's the main experience I had on this team.

If you haven't read about the overview of the season this year, I would recommend doing that first here. For those of you who don't have the time (or don't care to read it) the tldr is that we decided to do a one year build cycle for the 2024/25 season. This is incredibly ambitious for a team as small as ours with only around 75 members (and like 25 actually active ones). Since we are building a hybrid vehicle, the accumulator (battery system) is very important to getting the car running full hybrid. On a team like this, there are some things you can get away with and some things that have to get done - this is one of those things you just have to get done.

I have no experience with battery systems. I have no experience with cars. I barely have experience with building stuff; but I was honestly really eager to figure this out. I wanted to help out in any way I could and I felt like I hadn’t been helping too much for the first couple weeks of the semester. So - first night we are assigned to the project and there has been no progress so far. I learned we are using an Orion BMS2 which is an off the shelf battery management system. I was told by our electrical hardware team lead at the time that the thing had never even been turned on; so I’m like, great. We’re getting nowhere, right? So I work with the guy next to me to get this thing powered up and we manage to get it turned on day of. I wish I could say the rest of it would be that easy, honestly this gave us a false sense of hope for the rest of this project.

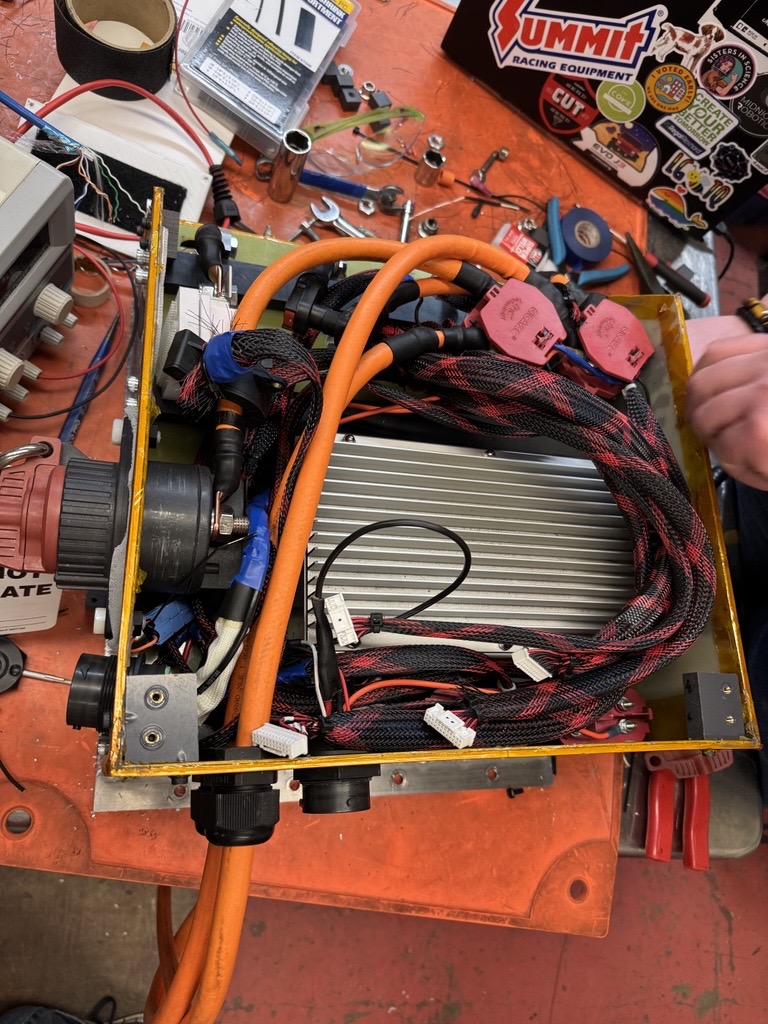

I worked on this for the rest of first semester and almost all of second semester as well. One of the biggest problems that we ran into was the mechanical/packaging constraints of our housing. We had to package all of this stuff pictured on the right into a tiny box. This decision was made because we wanted to reduce weight, and with weight reductions comes space reductions (at least, in this case). So, any time there was a problem it makes it even more difficult to troubleshoot.

I remember specifically we ran into an issue where a member of our team shorted between the two t-blocks at the front of the accumulator and welded a wrench to the metal which caused some damage to some of the cells. We removed the cells that were visibly damaged but kept getting weird faults on our BMS system, nothing seemed to make sense. Might I add, the process for changing cells is not simple at all. We had to take out each individual bolt holding the busbars in (terrifying, since our packaging does not allow for much space without risking a short), remove the bus bar, somehow get your fingers between the tightly packed cells, remove the damaged cells, replace them and then replace the bus bars. So, our packs seem to be randomly blowing fuses and throwing faults on our BMS. We troubleshot for hours and decided it must be an internal error with the cells. Luckily, we had extras so we replaced any cells that could have been affected by the original short.

That worked for us. We were then able to put the entire accumulator together, and all was well, and the car ran at competition full hybrid with no problems and everything was wonderful.

Right. And then I woke up. In reality, we put the entire thing together and then continued to have issues, specifically with the in-line fuses. Imagine, you just finished the hardest project you had ever worked on in your life and then had to take the entire thing apart. Tragic. But, it had to be done. So we take the accumulator apart once again, discover the blown fuses (or damaged, more likely, since we think the issue was in part due to the tight packaging that was squishing the fuses causing them to break) and fix the problem.

Eventually, the accumulator got put back together and made its way into the car. It took the entire year, but we got it done. I won’t even get into the issue we ran into once it was mounted in the car, because that was honestly embarrassing (we had the communication baud rate set to the wrong value, we thought our BMS was broken but it was, of course, user error). So, what did I learn? Well, a lot of things. For one, I learned that something will always find a way to go wrong, it's just part of the game; and honestly, I love it. Another thing is that throwing enough time and determination at something will give you enough luck to get your projects done. Showing up consistently and putting in work is the only reason this project got done, and I’m definitely going to carry that mentality through to this year to get things done.